Laser cutting

We put 2,000,000 pounds of steel 30 feet in the air to save space on our floor. What does that say about the lengths we’ll go to be more efficient?

Clean Cuts

Our metal fabrication process is built on precision and consistency. Using top-of-the-line technology and advanced cutting equipment, we deliver clean, accurate cuts on every project. From initial design to final fabrication, our investment in modern machinery ensures tight tolerances, smooth finishes, and dependable results—no matter the complexity of the job.

- Laser Cutting

- Tube Cutting

- Plate Cutting

- Mechanical Sawing

Laser cutting

Our laser automation—one of the only systems of its kind in the country—allows us to double our capacity while reducing the number of times we touch the steel.

Nitrogen cutting—well, it simply offers the cleanest cut you’re ever going to see in steel up to ¼”.

Now that might sound like a fabrication, but we’d love the chance to prove it to you.

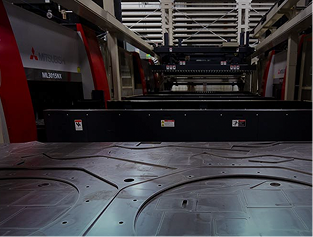

Tube Laser cutting

If you’re surprised to hear we have tube laser cutting capabilities (because many shops don’t), wait until you see what they can do.

Three, six-axis machines offer any cut and every angle in a single program cycle.

- Part Size

- Wall Thickness

- Shape Capabilities

- Efficiencies

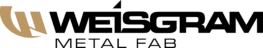

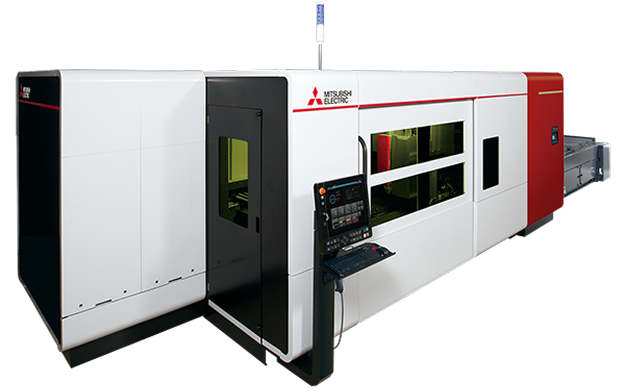

PLate Laser Cutting

Not only do our flat laser cutting systems allow us to offer massive throughput all day, every day, we know right to the minute when your parts will be cut.

1x

2,500-watt Mitsubishi fiber laser

- 60” x 120” Max Sheet Size

- 1″ Max Material Thickness

8x

6,000-watt Mitsubishi lasers

- 60” x 120” Max Sheet Size

- 1″ Max Material Thickness

- 1.93 Million Pounds of Steel Stored Vertically

- 24/7 Material Tracking

- Full Automation

- Automatically Inventories Material

- Unmanned Operation for Extended Periods

- Run Back-to-Back Jobs with Little or No Supervision

- Reduces Need for Manual Operators

- Reduces Time Searching for and Transferring Materials and Products

- Minimizes Material Damage

- Lowers Liability Risk

Mechanical Sawing

When it comes to sawing, few folks in the Midwest are capable of doing what Weisgram does every day. Even fewer can do it as fast.

CNC Controlled Sawing

20” x 25” Capacity

60° Mitering, Right and Left

4’ and 8’ Shuttle Lengths

Automated Material Handling

Mill Bundle Capacity

Production Workflow

We designed our fabrication workflow to minimize downtime, reduce rework, and move parts efficiently through production. Every process is documented, every weld is traceable, and every finished part is measured against your exact requirements.